What is a CNC Router?

What is a CNC Router?

Today’s desktop CNC routers can accurately cut multiple parts and can cut decorative carving. The new smaller machines are also much more affordable than their industrial big brothers.

Maybe you’ve been to a big woodworking show before and were mesmerized by the immense, industrial CNC (Computer Numeric Control) machines. Full sheets of plywood slide in one end and cabinet parts — complete with joinery cuts, holes for shelving pins, pilots for mounting screws and even decorative grooving — emerge on the other.

Of course, many of these machines cost more than the average home and are nearly as big, but these days some manufacturers are making downsized machines, called desktop CNC routers. Now, you can buy a turn-key package for under $3000, bolt the parts together in an hour or so, load a program into your home computer and, by the end of the day, start doing some real CNC woodworking.

Today’s desktop CNC routers can’t slice a plywood sheet into cabinet parts, but they can cut small parts — drawer fronts, for example, or door panels — complete with joinery cuts, profiling and decorative carving. They’ll mill a rough board smooth or texture a smooth board to make it rough. Where they really excel is in making signs and relief carvings. They are pretty easy to use, have many practical applications and are reasonably affordable.

How Do They Work?

You do need a computer and a CAD (Computer-Assisted Design) program to run them. Typically a desktop CNC router will come with a version of a CAD software program so you can draw what you want to cut. Then you switch to some sort of toolpath program, also provided with the machine. There you select the cutter (or cutters) you intend to use. The software calculates the cutting instructions and the calculation yields a file that you can name and save. Next, you secure the wood in the machine, install the correct bit, and begin the routing process.

The cutting action happens automatically. Typically, standard router bits are used, but special adapters may be necessary to fit the bit in the collet. The bit must extend a precise distance beyond the adapter or collet. The required extension varies from bit to bit and is specified in the machine’s manual.

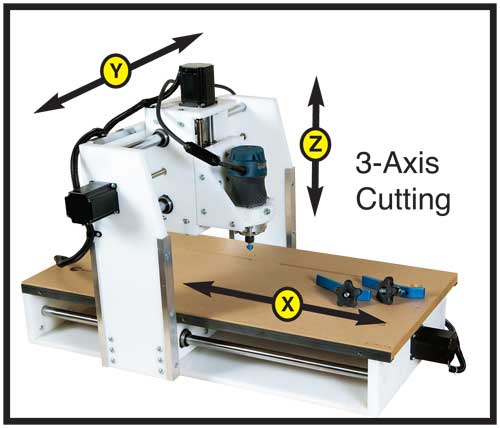

CNC routers cut in what are called three axes or directions. Up and down is the Z coordinate or axis. Think of left and right as the Y-axis. Forward and back could be called the X-axis. With a variety of bits and a computer program working in those three directions, the sky’s the limit. However, the overall size of the machine’s bed and cutting range will determine the maximum workpiece size you can manipulate.

CNC Makes Cutting Patterns Easy

When it comes to considering investing in a desktop CNC system, just imagine the process of creating and using templates in a typical project situation, such as contouring the bottom edge of a table’s apron. First you might draw the contour freehand to determine the shape you want, or you use a CAD program to draw the contour. Then you’ll try to duplicate that shape onto a piece of sheet stock and enlarging it to create your template. From there you saw the line, sand it and, if it looks right, trace along its edge onto each apron workpiece. After rough-cutting the shape, you reattach your template in order to pattern-rout it to final size. With CNC, you could draw the shape once in CAD and use the CNC to cut the apron workpieces directly. No need for a separate template. No sawing and sanding and sawing again. And if you wanted to save the template to use again in the future, it’s on your computer’s hard drive. No clutter of dust-collecting templates in the shop.

There could be real and practical advantages to consider incorporating a desktop CNC system into your woodworking pursuits. You could save time, improve accuracy and even expand your range of creative possibilities with your projects.

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home